Parts I bought to put in it:

I like SHS parts, What we have here are [SHS: 8mm bearings, V3; Double O-ring Cylinderhead, V3 AK nozzle W/ O-ring, cylinder and shims] and a V2 Metal spring guide.

Sadly the cylinder was to long to use and I already had a box of loose shims so I didn't need to use those.

So to remove the lower receiver you have to rotate and pullout this pin; You may need to push on the butt stock to make it come out easier because it's a tight fit:

Then pull the lower backwards, it'll stop but that's the catch so push harder until it "pops" out.

Then as you remove it rotate it downward:

To remove the gearbox remove these two screws, also keep check of the front screw. For mine only that particular screw will fit in the hole; the other one's head is slightly to big.

Also motor wiring, Check before you solder a new battery connector. I soldered the red stripe as positive but It was wired as negative. And couldn't figure out why it wasn't pulling the spring..

So now your gearbox is separated, push on the spring guide until it's flush with the gearbox and remove the pin:

The spring and guide will come out without any hassle:

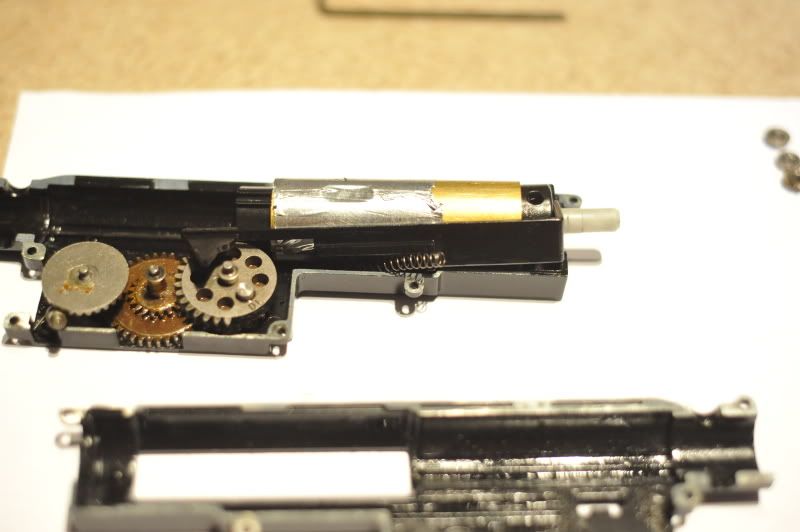

Now to remove the casing take your trusty 2.5mm hex wrench and remove the 3 screws with lock washers:

As you can see I have wrapped the cylinder with metal ducttape to close the hole. works pretty good and so far o issues.

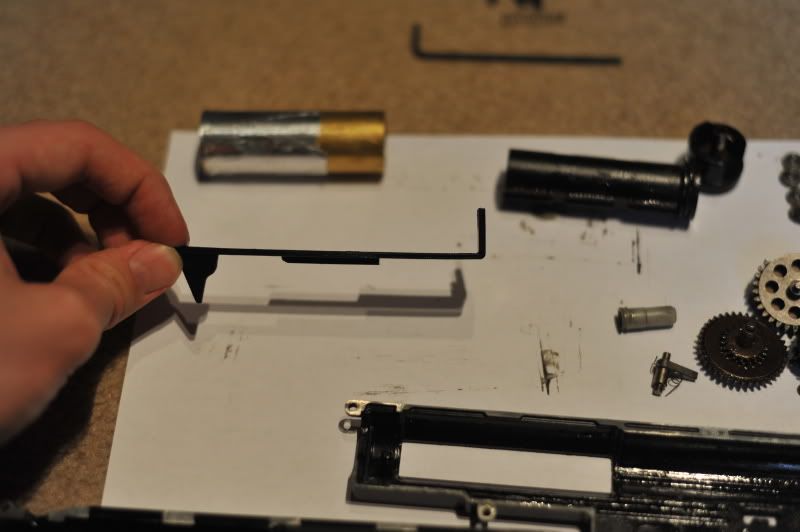

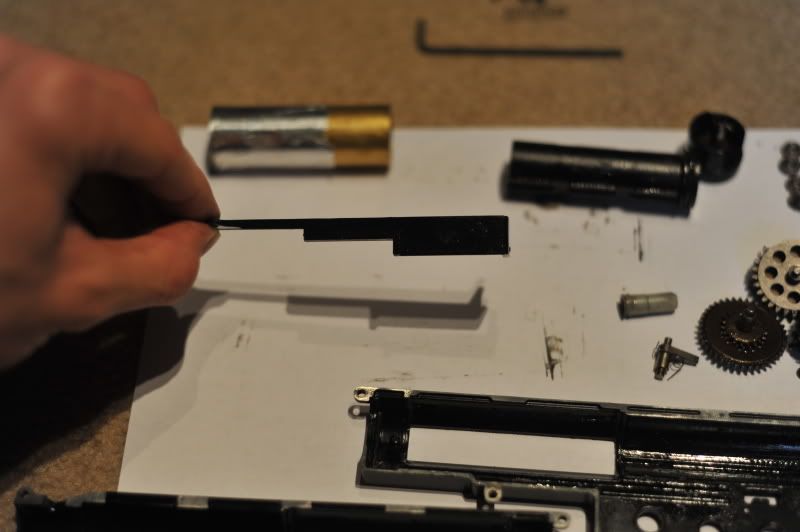

This is the tappet plate, this looks like a Ver6 to me. But I haven't taken the time to compare with my thompson.

Parts overall:

A nice polycarb piston with full metal halfteeth, I might change it to a poly-metal tooth in the future. The Pistonhead is alright, I changed the stock O-ring for a Danco #14 ring. Gears are decent with nice interlocking so for now I don't need to change those. The SHS parts fit nicely and the new bearings snapped into place unlike the china ones that just fell out when I opened the case. To re-assemble reverse the process :) P.S: You may or may not need to file down the rear of the motor case to fit certain motors.

ALSO: If you change the spring guide you will need to file the sides and the "pins" flat:

Some close up pictures:

Another thing to note is that the whole end of the barrel is separate and joined here:

And may become wobblely, this can cause the end of the barrel to be completely misaligned with the inner barrel. I fixed this by lining it up where I wanted it and put super glue in it to fill the empty space. And so far it's worked perfectly. I'd also go around and put glue over the pins just so they don't work them selves out over time.

I did try to remove the pin, but it was way too tight and decided best not to mess with it.

Update: 1/5/2013: Magazine not feeding after some use?

This could be the possible culprit. If you look at the slanted latch that keeps the BBs in the mag you can see that there is an indention on the center and right magazine. The left magazine is perfect, The center one only has a small indention but is still workable and the right magazine's latch is completely smashed and needs to be replaced. The dents catch the feed tube and stop it from pushing the latch back to release the BBs.

Better look at the right magazine:

I suggest you spray some silicone oil in there to help keep this from happening.